Alnico permanent magnet is an alloy composed of aluminum, nickel, cobalt, iron and other trace metal elements. Its metal composition is different, its magnetic properties are different, so its use is also different. There are two different production processes of alnico permanent magnet: Casting and sintering. Cast Al Ni Co process can be processed into different sizes and shapes, with high strength, strong corrosion resistance, good temperature stability, and the maximum working temperature can reach more than 600 ¡æ. Cast Al Ni Co products are widely used in various fields, such as sensors, instruments, electronics, electromechanical, medical treatment, teaching, automobile, aviation, military technology, etc

Process flow: raw materials ----- ingredients ----- smelting ----- heat treatment ----- magnetic inspection ----- grinding ----- finished inspection ----- packaging and shipment

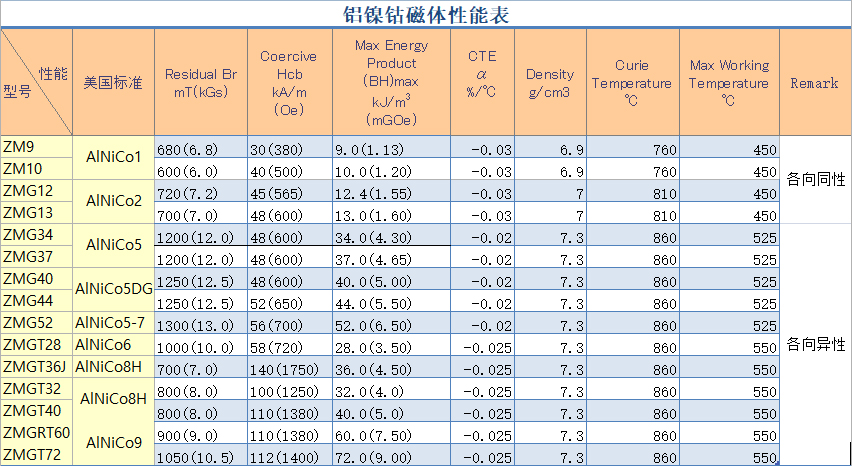

Main performance parameters of SmCo magnet:

¡¡

¡¡